Sean and I are no strangers to 3D printers. We use them at home and at work. At the time of this post Sean has three 3D printers; two Bukobot FDM printers and an IBox nano resin printer. I have a custom Bukobot and have built a pretty nice Kossel derived delta printer for work. It started as a Folgertech kit and then I heavily modified it.

So when I told Sean I wanted to buy one of the new FT-5 kits but was on the fence, he promptly forced me into pulling the trigger when he bought one for himself. I didn't expect him to want a 4th printer. I wanted the printer just because it had a bigger build volume than my Bukobot duo. Going from 200x200x220mm build volume to a 300x300x400mm might not sound that much bigger but it really makes a difference. Sure there will always be something that doesn't fit and you will always want a bigger machine but this is a very capable build size and at a price point of $500 for a kit how could we not try it out?

This post is aimed to be a review on the build and first impressions of the printer. Let's get started.

Box arrived weighing 45 lbs! Dog approved too.

Look at all these goodies.

This kit really is complete. It even came with candy!

After about 5 hours of sorting hardware and building on the first evening of building I had a completed frame. This thing is big.

After about 12 hours more spent on it I had something that almost resembles a printer. Ready for wiring!

It was at this point that I had to stop building for a while. I ran into a few issues.

1. One of the two belts for the z-axis was the wrong size. Folgertech found it more peculiar than I did because they don't even carry the size of belt that I received. They attributed it to a supplier issue. Folgertech sent a replacement set of Z belts.

2. My power supply was DOA. That is annoying but I actually had a really nice comparable PSU from Mean-Well that was from a previous build so I bolted that in instead. It barely slowed me down and Folgertech sent a new one.

3. The LCD screen was also DOA. Once again that is annoying but you don't need the screen to have a functioning printer so that didn't slow me down at all. Also Folgertech sent me a replacement with the power supply. No big deal.

When I got the new belts I continued the build, even modifying some stuff before finishing it by adding some lights to the gantry and hot end.

That ought to cast some light on the situation.

Adding 12V LED light strips is pretty straight forward but there are a couple of things to watch for.

1. Use the waterproof/resistant style LED strips as the coating applied to them will insulate the circuit and keep it from arcing on the aluminum extrusions.

2. Size is important as many LED strips are too wide to fit in the extrusions. I found that the strips containing the 3528 LED chips tend to fit. However if you want to just buy the same strip I bought, click on the picture below to purchase from Amazon.

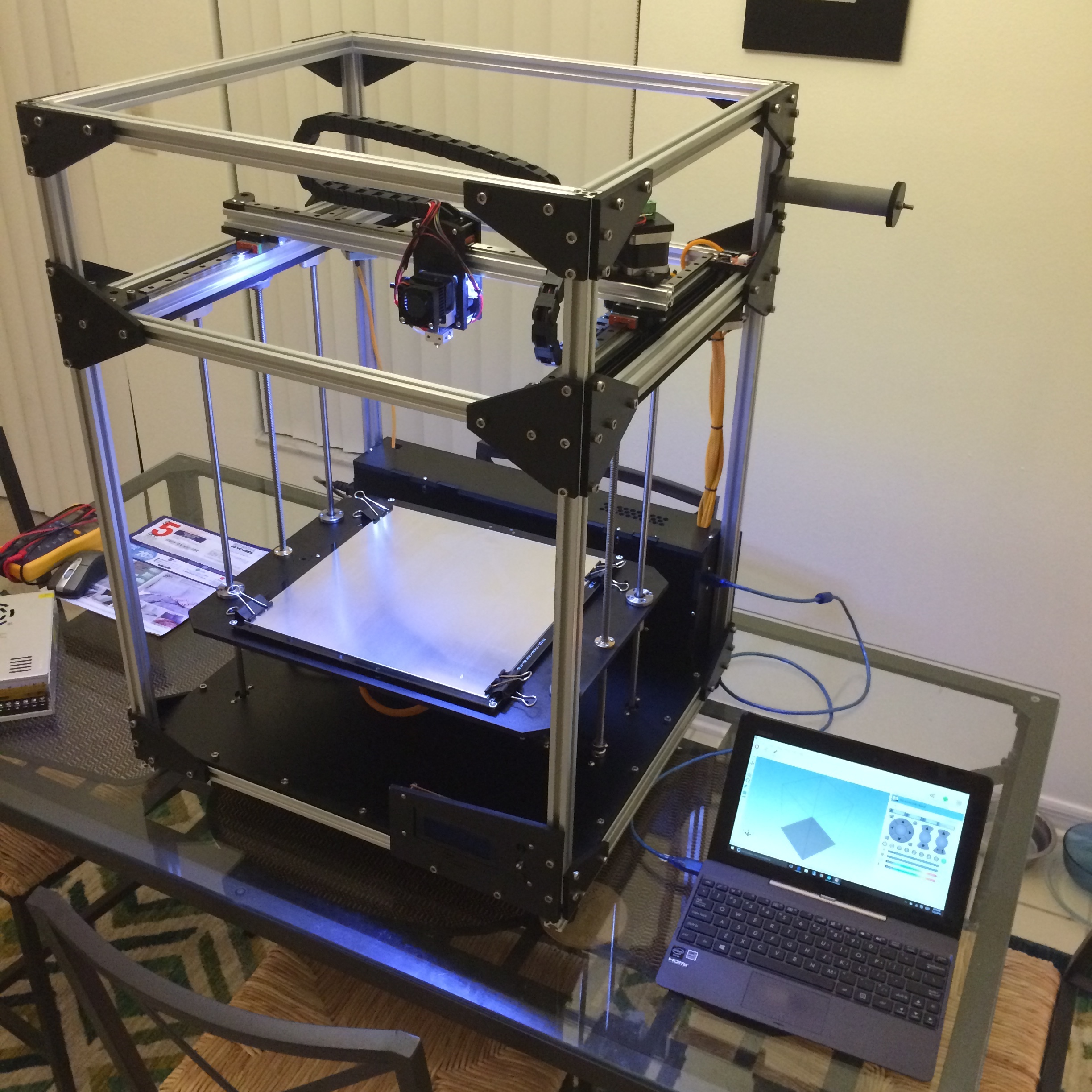

After an estimated 40 hours of building I was ready to do some quick tests and start dialing it in.

First run!

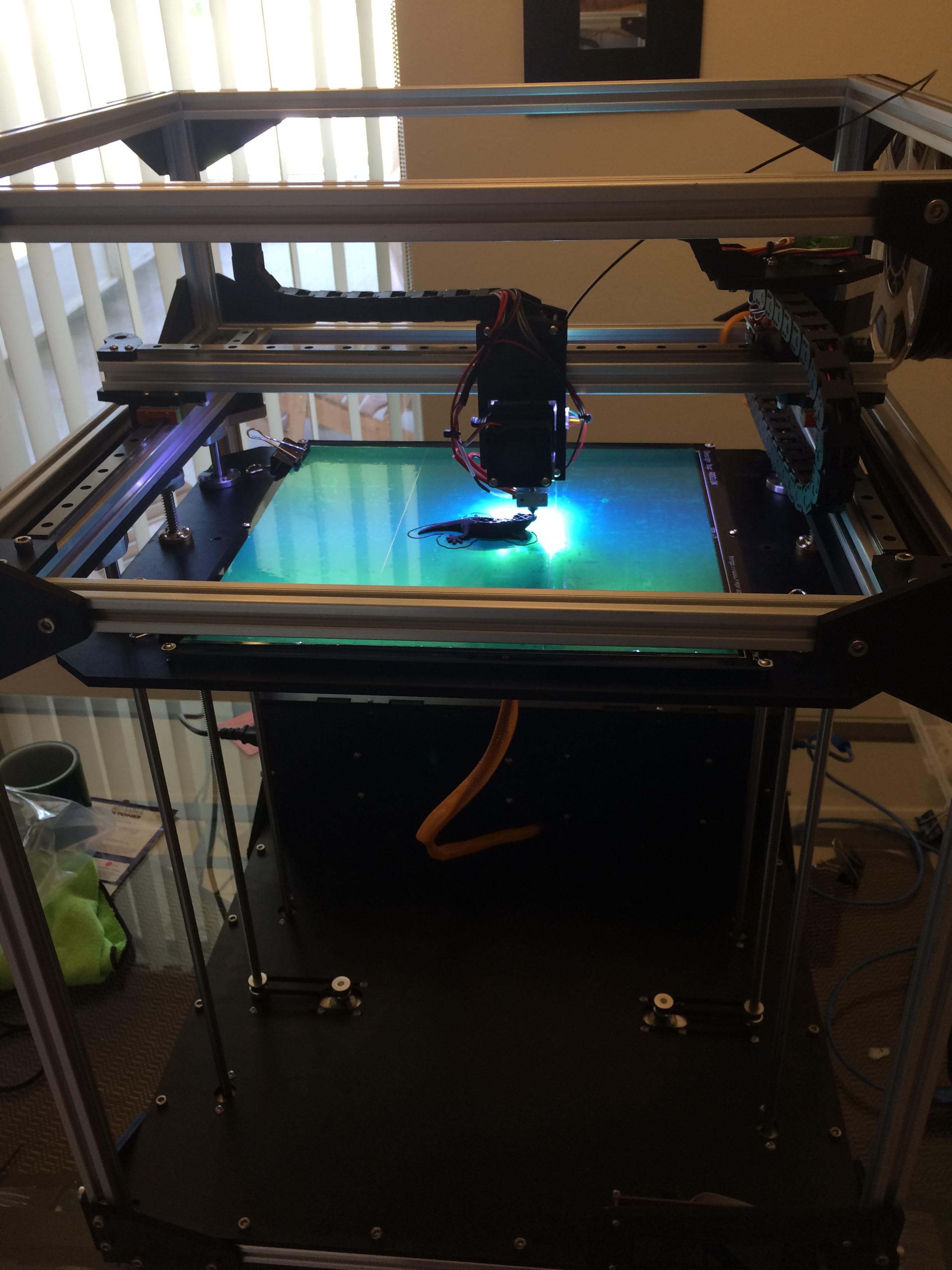

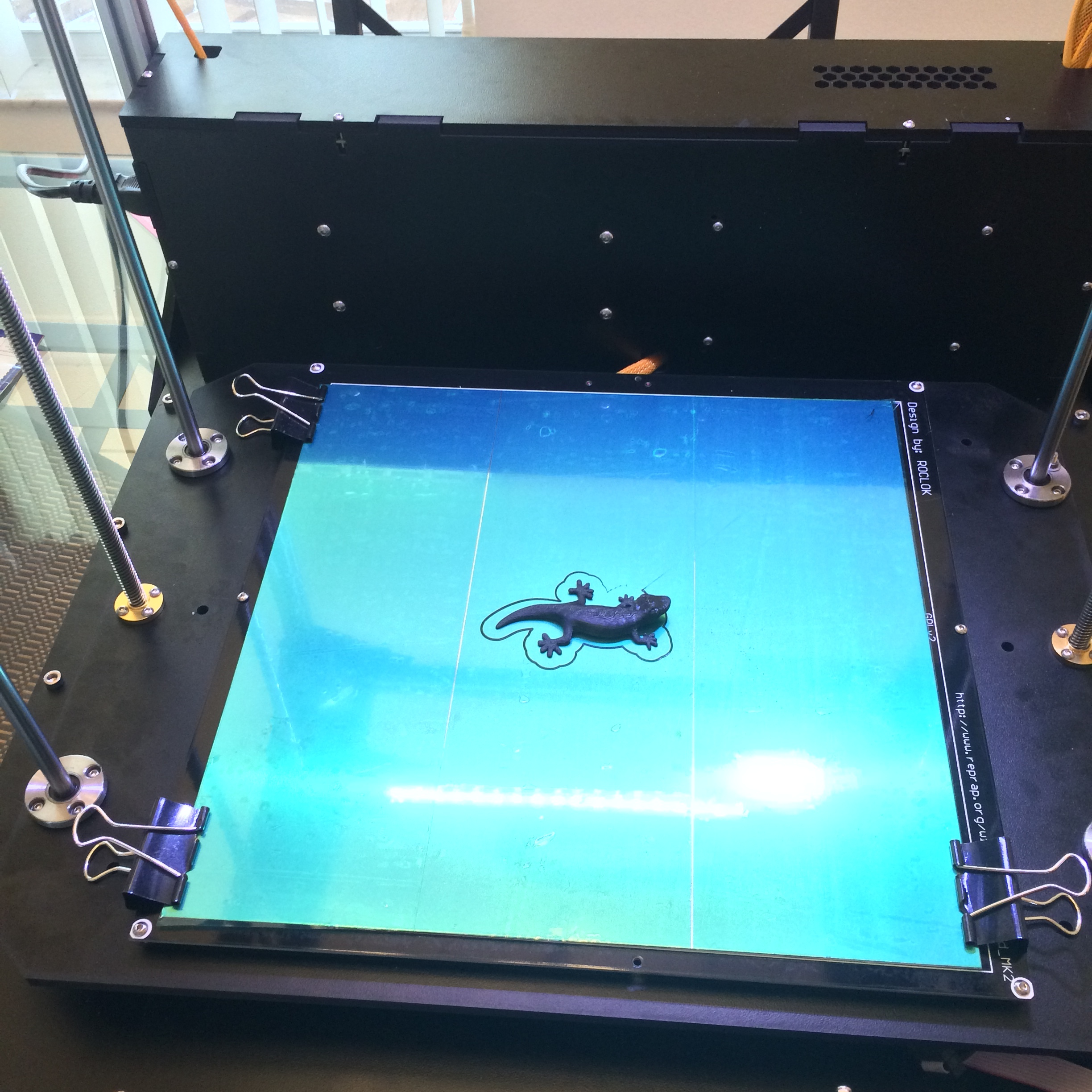

Success on the first attempt!

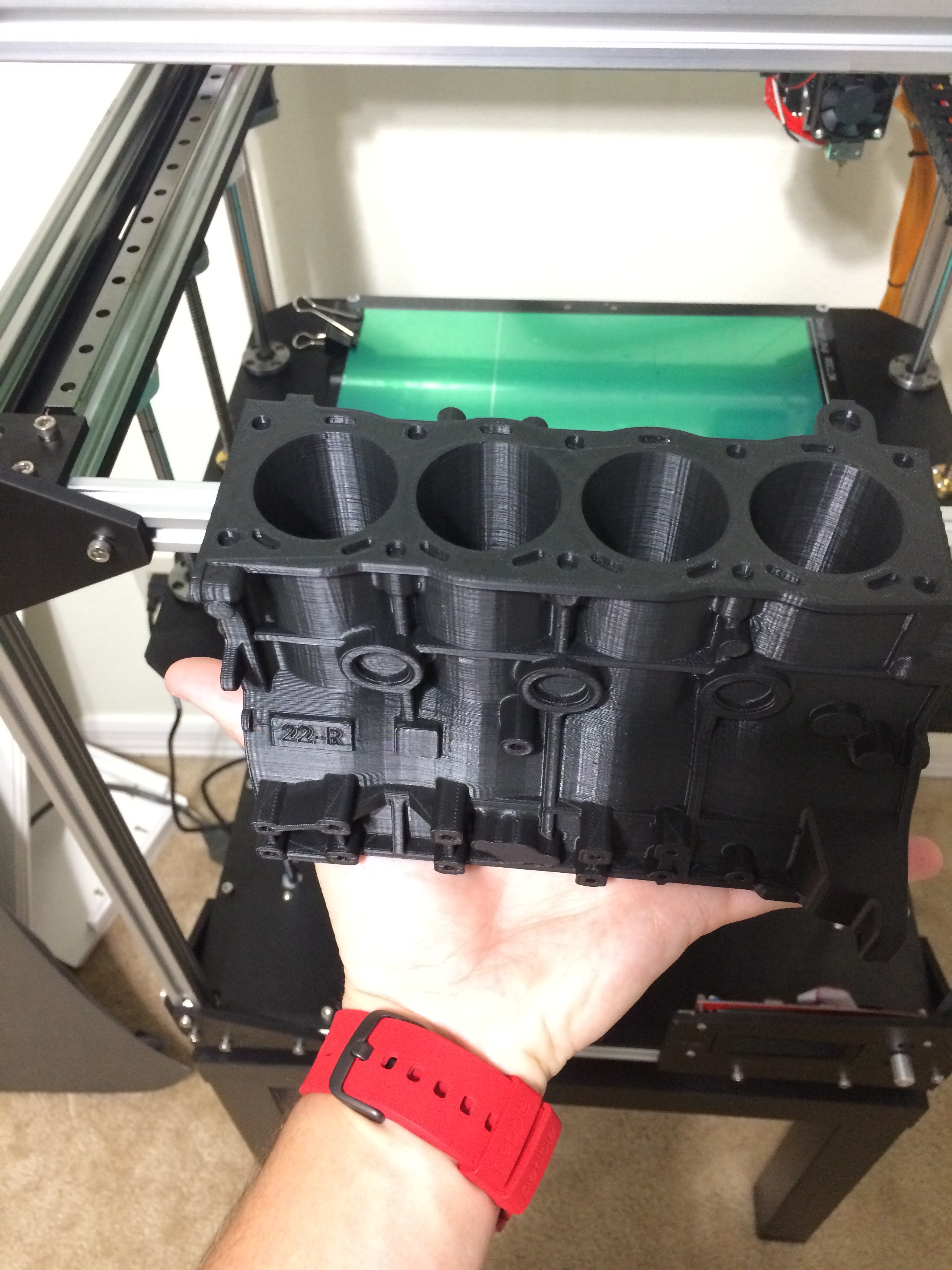

First larger print. Toyota 22RE block

To recap, I spent about 40 hours assembling this which I feel is decently quick considering I had a few hiccups with bad parts, made a few modifications along the way and generally wasn't in a rush to complete it. Those few problems I had with parts are unfortunate but honestly when you think about how little this printer costs and that it is a very good design, overall it's forgivable. I would highly recommend this printer as you won't find a cheaper printer with this size build volume and this well designed for anything close to this price point. If you are considering buying a 3D printer take a look at this one. You can buy it straight from Folgertech.

https://folgertech.com/products/folger-tech-ft-5-large-scale-3d-printer-kit

Sean still has to build his so we will find out if he has any problems along the way. We also have another friend who is midway through building his and so far so good. When Sean runs out of excuses for why his isn't built yet we plan to do an assembly video illustrating tips and tricks along the way.

I also will be posting modifications I make to it along the way and we may do some videos for those too so keep an eye on this site.