If you found this page chances are you only found it because you Google searched "Tiko 3D printer review." We don't have a lot of followers yet, probably because we don't have a lot of content on this site yet. The only other content that regularly brings visitors to this site is my review of the Folgertech FT-5.

I backed the Kickstarter campaign for the Tiko back in April of 2015 with a backer number of around 73XX. The price for a Tiko was discounted over the $199 they planned to ask for them down to $179 + S&H. There was no estimated price for shipping but, "Hey how much could that cost? Right?" Estimated delivery was December of 2015. Kickstarter campaigns are almost always late so I wasn't going to hold them to that too much at that point but if they made it in time for Christmas I could give it to my nephew as a Christmas present. If it ended up arriving in January I could give it to him for his birthday. Great!

Fast forward to now. It arrived mid-January of 2016; a year later than promised. This was the second 3D printer I ever purchased but in between funding it and receiving it I actually built 3 others. Shipping cost was around $50 too. Ouch. Oh well that is still a pretty cheap printer and it did come with a full spool of filament as promised. The pre-order price on the Tiko website is $199 so I can't help but wonder what the shipping price will be once they are in stock in the U.S. But maybe the price difference (if any) is my contribution to seeing a great idea flourish and put affordable printers in the hands of everyone. That would be worth the wait and added cost of backing the campaign; and that is kind of the point of crowd funding.

So let's discuss the printer itself.

Even though this is a present for my nephew I still had to try it out and do this review. He knew that was part of the deal.

When I opened the box and pulled it out I realized something was wrong right away. The acrylic portion of the body had broken free from the main body. I remember hearing an update during the campaign that they had an issue with the glue that holds the acrylic to the main body. Well they definitely fixed that because the glue is still attached to the acrylic and the main body but the acrylic cracked all around the glued portions.

I assume this happened during shipping so I figured I would contact their customer support. After all the printer sits on this piece and you have to pick the whole printer up off the build plate in order to remove your print. This part will be handled frequently.

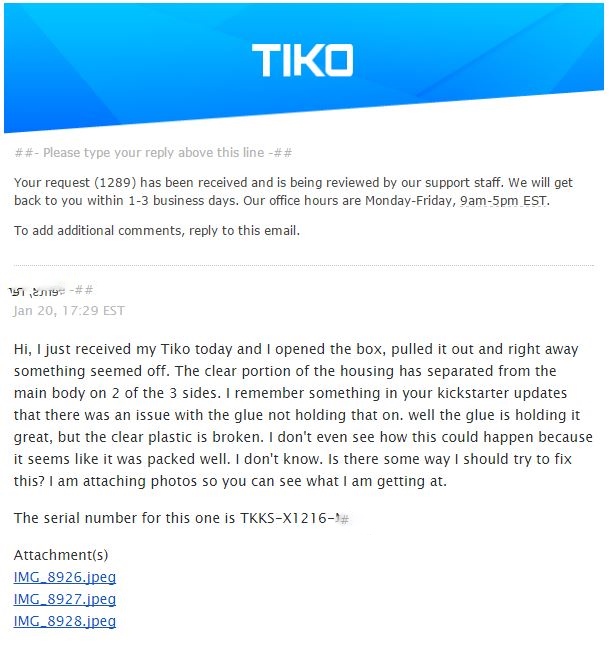

The email I sent.

The email I received.

I wasn't that happy with the reply I received. I wouldn't exactly call it cosmetic damage since it is the structure of the printer; which is actually on of their selling points on this printer. The body is the frame and its supposed to be free from defects, misalignment, etc.

I felt that I had just been brushed off so I sent a reply stating that, but that I would try gluing it. I did manage to glue it and I used a high temperature hot glue so that I wouldn't get super glue vapor clouding on the clear acrylic. It seems to be holding fine, but every time I pick it up I am afraid I am going to break it more and then it is garbage.

But how does it print?

I'm getting there but first we have to connect to it. The only way to connect to the Tiko is over wifi. It is supposed to act like its own print server. All slicing and programming is done through your web browser. When you open the box there is a quick start guide that explains how you should connect directly to it over wifi. It asks for your networks SSID and password and then tells you that it is going to connect to your network and you should reconnect to your network. Before disconnecting I noticed that it said it was going to download a firmware update. The interior lights flash showing a pattern where it looks like it installed an update and restarted. It never joined the network. So I reconnected directly to it and repeated the SSID and password for it. Once again it didn't connect. I tried a 3rd time, unsuccessfully, and then searched online for an answer. As it turns out "cloud printing" is disabled for now. The only way to use this printer is to connect directly to it like Ad-Hoc.

At first that just seems like a minor annoyance but actually that could be a problem. When the printer is idle and powered on it is hosting its own SSID and anyone can connect to it and use it because there isn't even a password. You just connect to it and you don't even have to know a special web address to access it because 192.168.1.1 works just fine. Now its probably unlikely that any of my neighbors are going to connect to a random SSID with the word Tiko in it surrounded by seemingly random alpha-numeric characters but this could be an issue somewhere like a college dorm or apartment building. Someone could connect, go to a standard web address for causing mischief of 192.168.1.1, find a 3D printer, drop in a stl file or load the demo file and hit print. They would have no idea that you have a finished print still sitting on the print bed and then the printer crashed into it making a big mess and most likely destroying it.

Okay that is annoying, but seriously, how does it print?

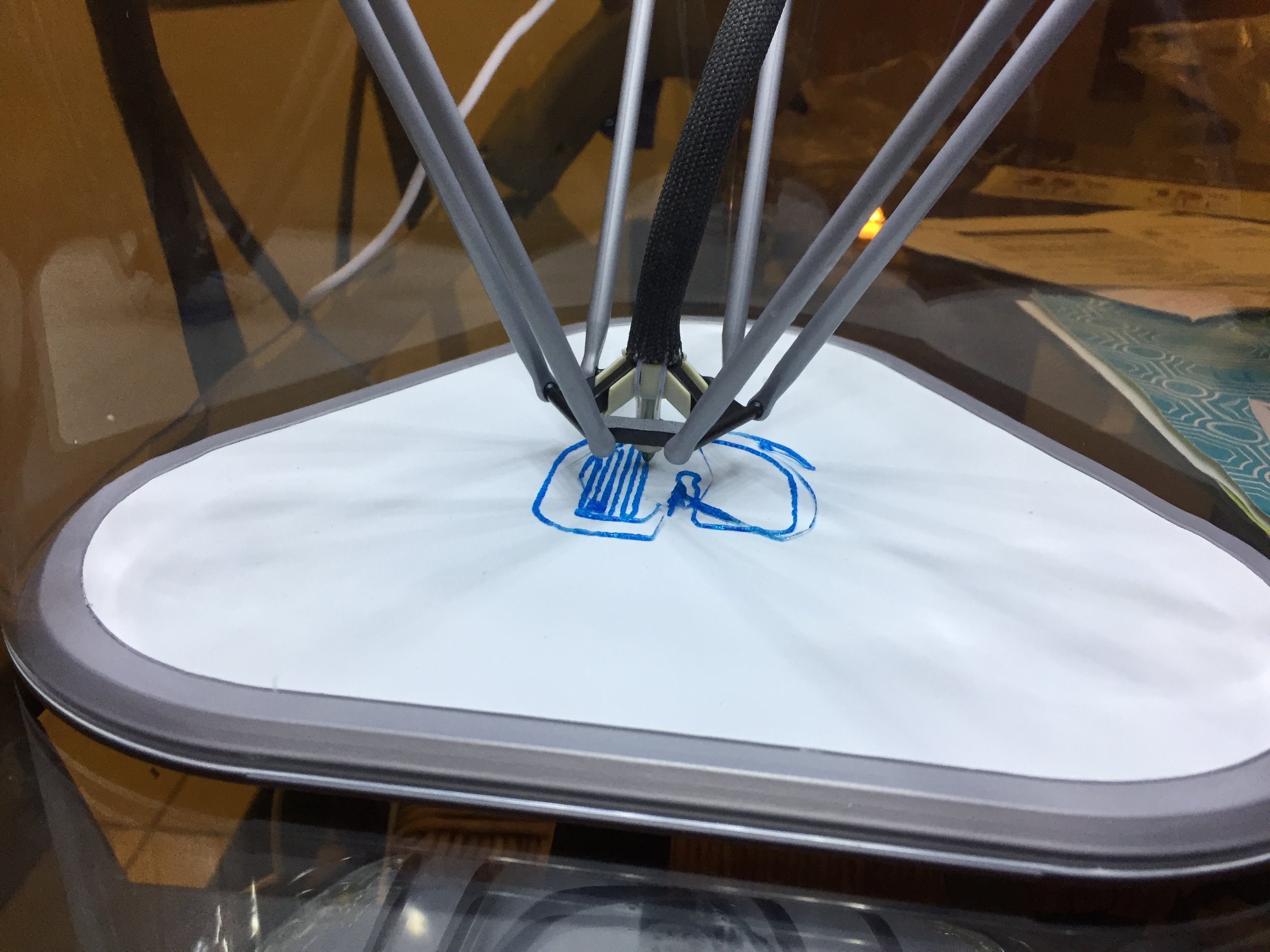

Loading filament wasn't the smoothest ever but I did get it to work fairly quickly. I loaded a file to test with, told it to slice using the factory default settings and hit print. It then ran its auto calibration routine which is rather odd and I am not sure how effective it really is. It drives to a location under each "tower" and presses the nozzle against the build plate. I assume it is watching the current load on the stepper motors while counting how many steps it had to do to get to a certain load. It is a neat routine but since the build surface is pretty soft it seems to be leaving dimples in the surface which is creating low spots at each of the 3 points it checks. Time will tell if this is a really effective routine.

After it finds this plane to print on it begins warming the nozzle. The Tiko has no heated bed or fans of any kind. The nozzle seems to be of a low wattage and the stepper motors are also really tiny. This is a very low power printer, however it does heat the nozzle in a reasonable amount of time. After it heats it begins laying down a raft to print the object on.

Not exactly the smoothest first layer or raft but lets see how much better it gets.

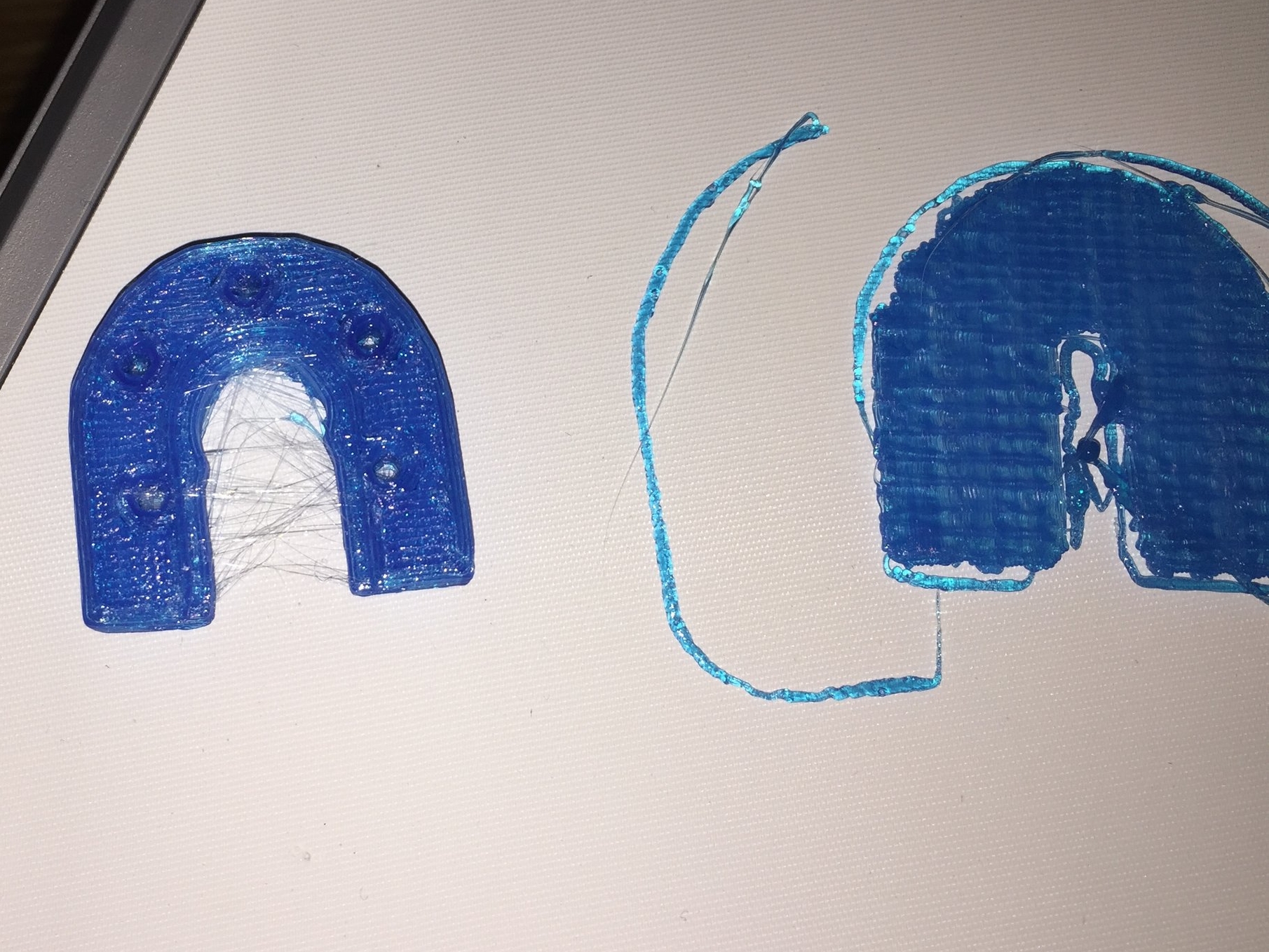

Well that is sort of disappointing looking.

It's far from a clean print but it did peel off the raft pretty well. It isn't great though. This is supposed be a hotend mount for a kossel style delta printer that I am working on. I had just printed a nice one on the FT-5 so I wasn't impressed with this. The second print I did came out horrid. It must have globbed somewhere and then one or more stepper motors lost position and it made a mess of the print.

Initial Impressions

Honestly I am pretty disappointed. There are a lot of cons to this printer and I am struggling to find some pros. I knew it was a small printer with a small build area so I can't knock anything off for that. It also uses non-standard filament rolls but I don't think that is too much of an issue either.

Cons:

1. It is amazingly slow. It took over an hour to print that part using the highest layer height available (0.2mm) and default infill and perimeters. So slow. I can get past that though.

2. Printing a simple object using default settings produced something of pretty low quality. I am sure as I play with settings I can get a little better performance out of it but I don't see anything great happening in the near future.

3. The interface is lacking functionality and security. I am confident they will work out the bugs on that but I won't hold my breath since there is no timeline given. If their software development is anything like the delays for manufacturing its going to be a while.

4. It seems super fragile when you take into consideration that it was damaged while shipped in a box with form fitting foam material.

5. Customer service didn't really serve the customer all that well in my case. It is true that I did offer the suggestion of just fixing it myself but that was more of a "I'm going to glue this if you don't help me." I am also confident I could replace the acrylic portion without damaging the main body. Finally I would have been fine with sending the whole thing back and getting a replacement (if they have any to replace it with). The real issue was them calling it "cosmetic damage."

Pros:

1. It has some cool led lights inside it and looks fancy and modern.

2. Wifi enabled?

3. Its a delta style printer and delta printers are cool..... I guess you can't really see how cool it is though because its motions are mostly hidden.

The Verdict

At this point I can't recommend this printer to anyone. I'll keep working on trying to get good prints out of it with my nephew and hopefully the Tiko guys can get their software improved but I feel like I wasted money on it.